Follow Us

Join our newsletter

Get the latest news delivered to your inbox

Thank you for contacting us.

We will get back to you as soon as possible

We will get back to you as soon as possible

Oops, there was an error sending your message.

Please try again later

Please try again later

Gripper Arms vs. Suction Cups: Choosing the Right EOAT for Your Needs

Morali EOAT Handlingsolutions INC.

Gripper Arms vs. Suction Cups:

Choosing the Right EOAT for Your Needs

Choosing the Right EOAT for Your Needs

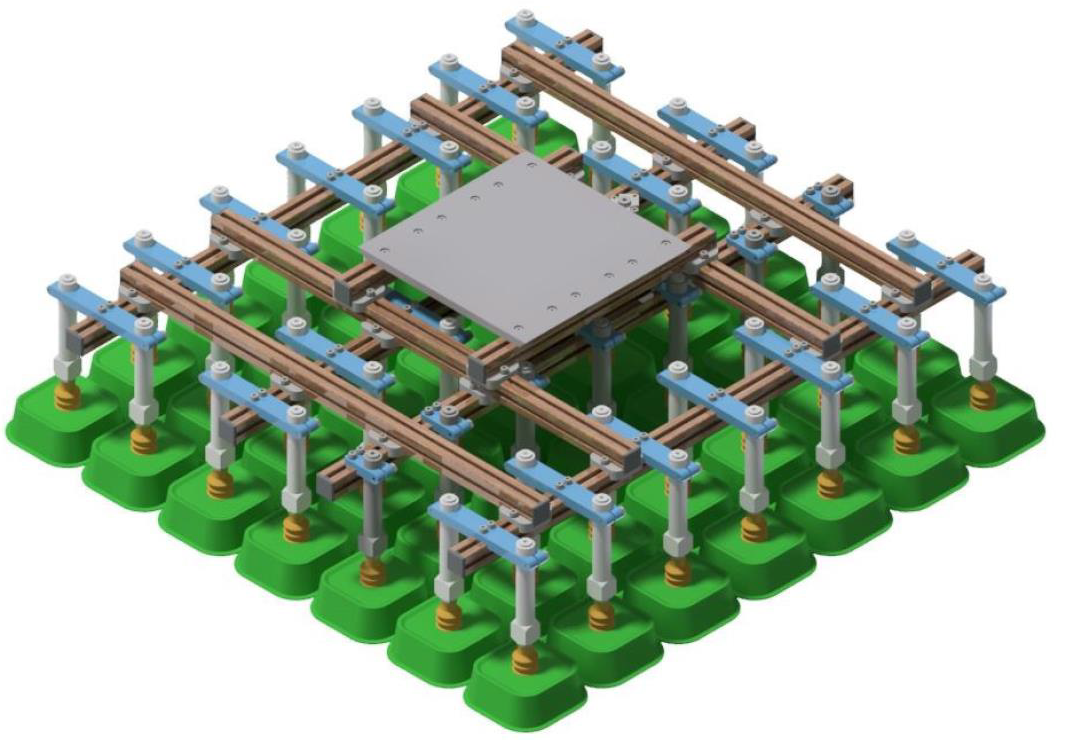

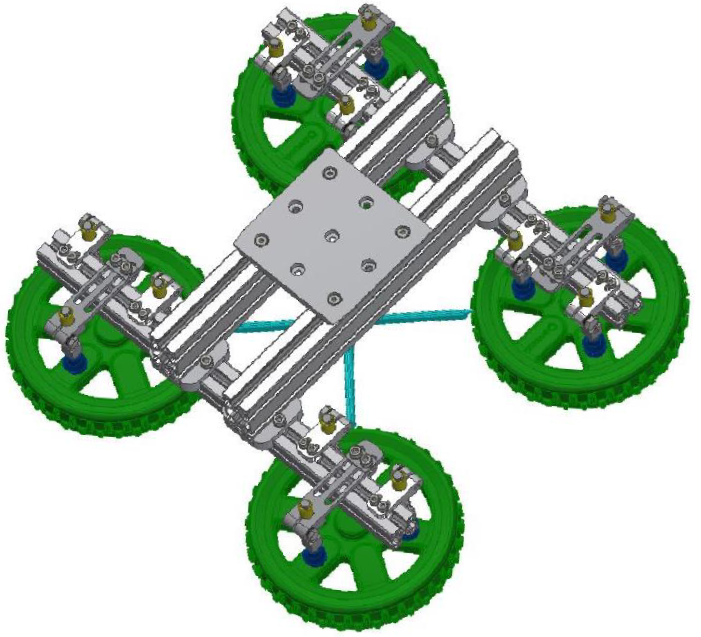

In the realm of automation, EOAT’s play a crucial role in enhancing efficiency and productivity. EOATs are responsible for gripping, handling, and manipulating objects in various industrial applications. Gripper arms and suction cups are the primary choices when it comes to EOATs. Both options offer distinct advantages and are suitable for different scenarios.

Let’s explore the characteristics and applications of gripper arms and suction cups to help you make an informed decision when selecting the appropriate EOAT for your project.

Gripper Arms: Strength and Versatility

Gripper arms

are mechanical devices designed to grip and hold objects securely. They come in multiple variations such as pneumatic, hydraulic, or electric, each with its own unique benefits. Gripper arms are known for their strength and versatility, making them ideal for applications that require any kind of heavy lifting.

One of the key advantages of gripper arms is their ability to exert a significant amount of force on the object being handled. This attribute allows them to handle robust materials, withstand high-speed operations, and firmly grip objects with varying sizes and shapes. Gripper arms can be equipped with customizable fingers or jaws to match specific requirements, promising a secure grip.

Finally, gripper arms are widely used in industries that demand precise and repeated movements. They offer exceptional control over the gripping force, allowing for delicate handling of fragile objects. Gripper arms are seen in manufacturing processes, assembly lines, and robotic

applications where accuracy and reliability are necessary.

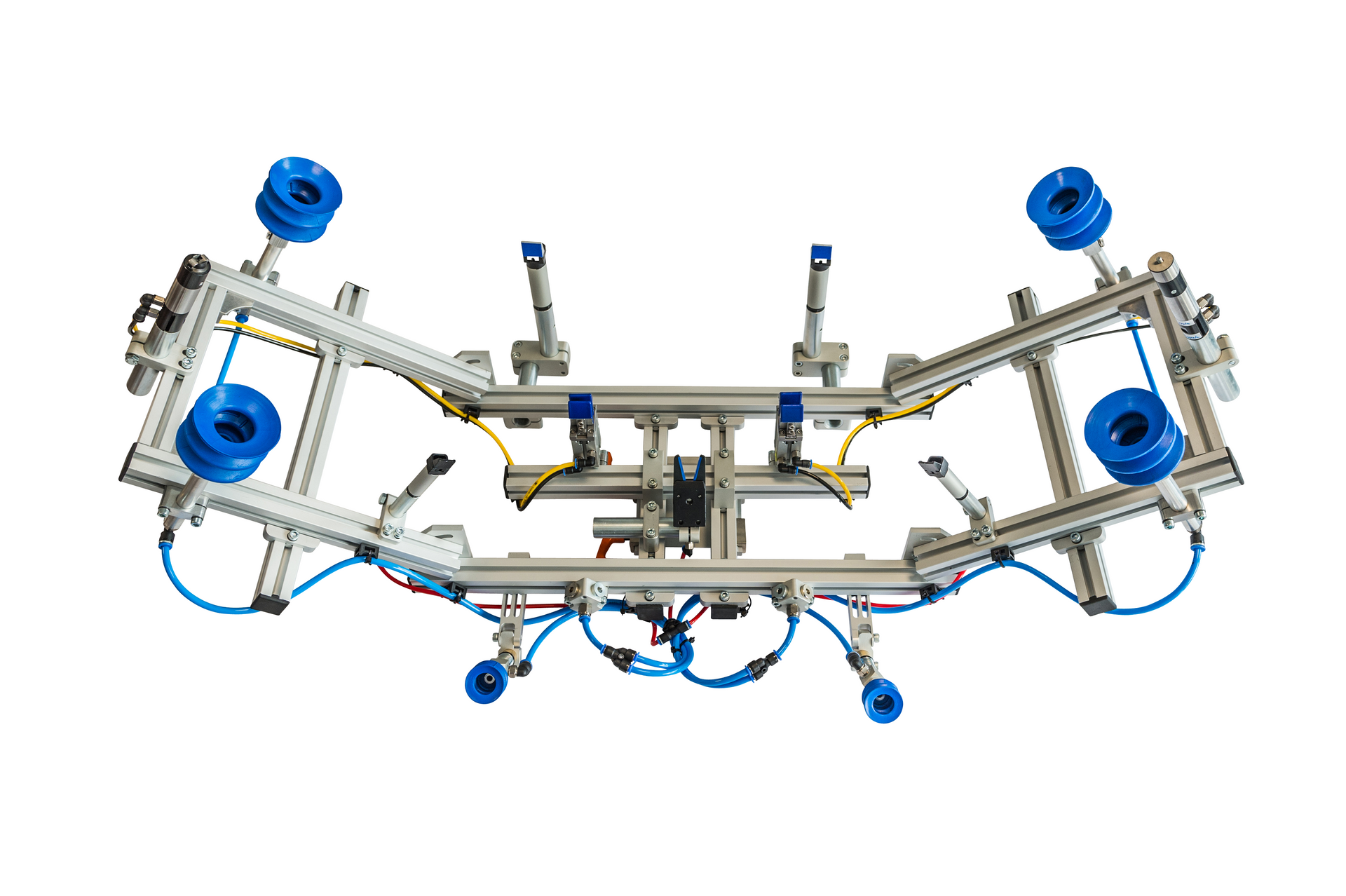

Suction Cups: Versatility and Surface Adaptability

Suction cups, on the other hand, utilize negative pressure to create a vacuum seal between the EOAT and the object being handled. This vacuum force allows suction cups to adhere to smooth surfaces and hold objects firmly. Suction cups are highly versatile and find extensive use in applications where airtight gripping is required such as with an egg.

One of the notable advantages of suction cups is their adaptability to various shapes and sizes. They can conform to curved or irregular surfaces, making them suitable for handling objects with non-uniform geometries. Suction cups are often used in industries such as packaging, logistics, and materials handling, where they can efficiently lift and move objects like glass, metal sheets, and other smooth-surfaced materials.

Additionally, suction cups offer a non-marking gripping solution. Since they rely on suction rather than physical contact, they can securely hold objects without leaving any significant marks or imprints. This characteristic is especially crucial in industries where the appearance and quality of the handled objects need to be preserved.

Choosing the Right EOAT:

When deciding between gripper arms and suction cups for your EOAT, several factors should be considered. First and foremost, analyze the nature of the objects to be handled. Gripper arms are more suitable for heavy or irregular objects, while suction cups excel in gripping smooth surfaces.

Next, evaluate the required gripping force and the delicacy of the objects. Gripper arms can provide robust gripping strength, while suction cups offer a gentle touch for fragile items.

Furthermore, consider the surface condition of the objects. Suction cups are highly adaptable to smooth surfaces, while gripper arms can handle a wider range of surfaces and materials.

Lastly, take into account the specific application requirements such as speed, precision, and repeatability. Gripper arms are favored in applications that demand precise control and high-speed operations, whereas suction cups are known for their ease of use and adaptability to various tasks.

In Conclusion:

Selecting the right EOAT for your automation needs requires careful consideration of the object characteristics, gripping force requirements, surface adaptability, and specific application demands. Gripper arms and suction cups offer distinct

April 16, 2023

Liebe Interessenten, wir freuen uns Ihnen mitteilen zu dürfen, dass wir als Klimaneutrales Unternehmen und von der IMC GmbH mit ISO 14001 zertifiziert wurden.

By MORALI EOAT HANDLINGSOLUTIONS INC.

•

April 3, 2023

In this blog, we share an amazing experience with you about this task of handling Morali pens and Morali name dices with an automated process. This experience let us reflect back to the MOTEK exhibition in stuttgart in year 2019.

By udag

•

April 3, 2023

There are so many good reasons to communicate with site visitors. Tell them about sales and new products or update them with tips and information.

February 15, 2023

The packaging sector is one of the successful market which is continuisly developing and increasing. There are many and various packaging materials, such as bottle, tubes, carton and blister. We have the suitable suction cup for each packaging material. Please send us your request and you will get a consultation and sample for testing and see for yourself.

January 16, 2023

Die Wiedererkennung eines Unternehmens und einer Marke gewinnt immer mehr an Bedeutung. Das Firmenlogo und die Firmenfarben sind die wichtigen Eigenschaften, die zur Wiedererkennung beitragen. Möchten Sie, bei ihrem nächsten Messeauftritt ihre Exponate besonders hervorstechen?