Follow Us

Join our newsletter

We will get back to you as soon as possible

Please try again later

Menu

Flexible application

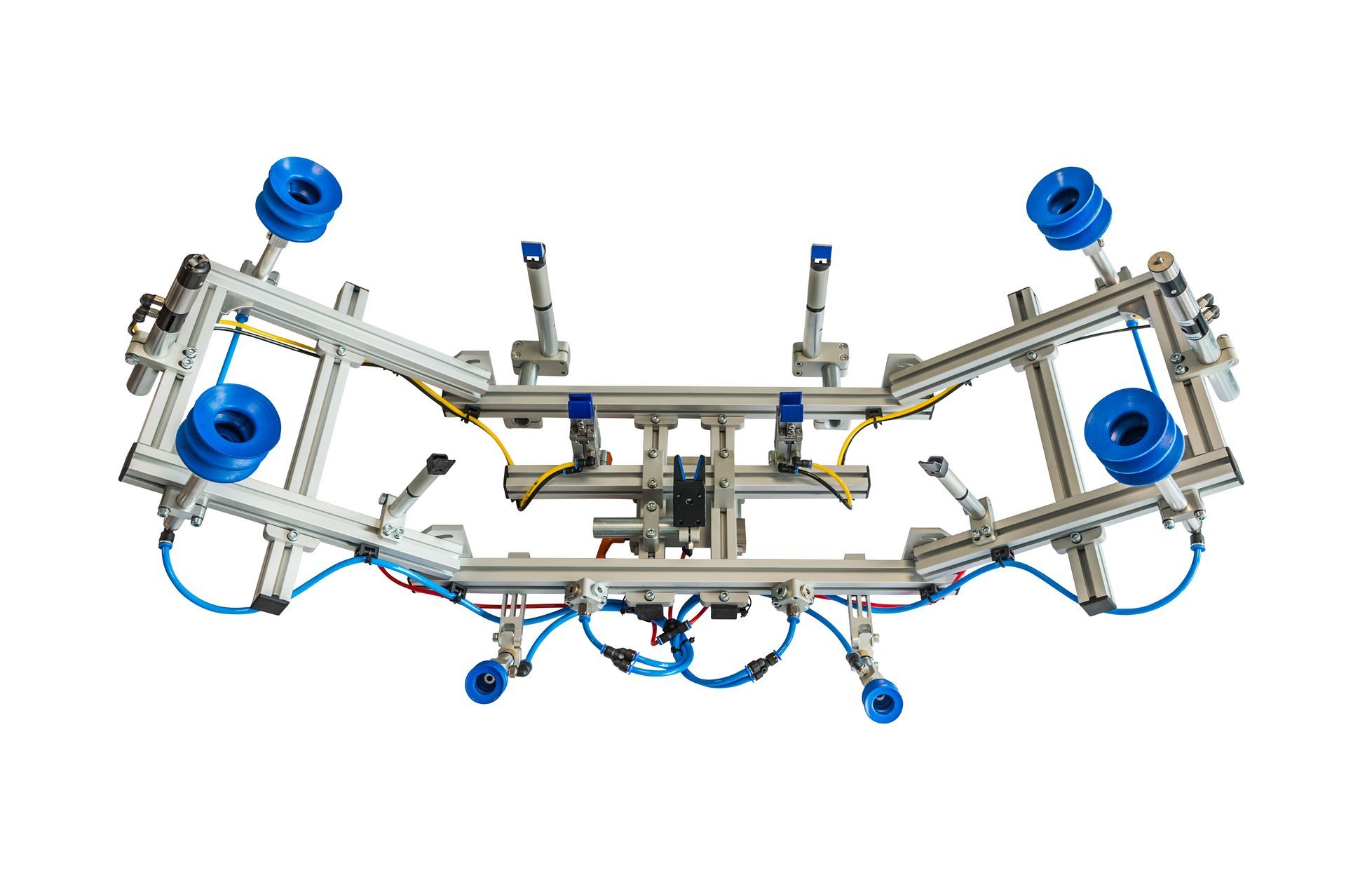

Removal gripper for a plastic part (as demonstrated in this video ) for a safety removal of this part from a mould.

This gripper solution includes a cutting pliers to cut the sprue part and is designed that the sprue part can be at same time removed from the mould. This allows reducing production time, since this gripper by removal task, cutes the sprue in a safety way.

A light profile and a quick changer which were selected according to the customer need. The last one was been cuted through laser technology and saved weight and time.

In addition to this the illustrated suction cups are anti marking and can absorbe temperature until 200°C, and are resistant to oil, and ozone can pick uneven surfaces smoothly.

Dieser Greifer lässt sich sowohl an Lineareinheiten als auch an Industrierobotern (6-Achs) montieren.

Few cases

Customer oriented solutions

Just grippers in CNC and additive technologies

Coordinated actions

Bildtitel

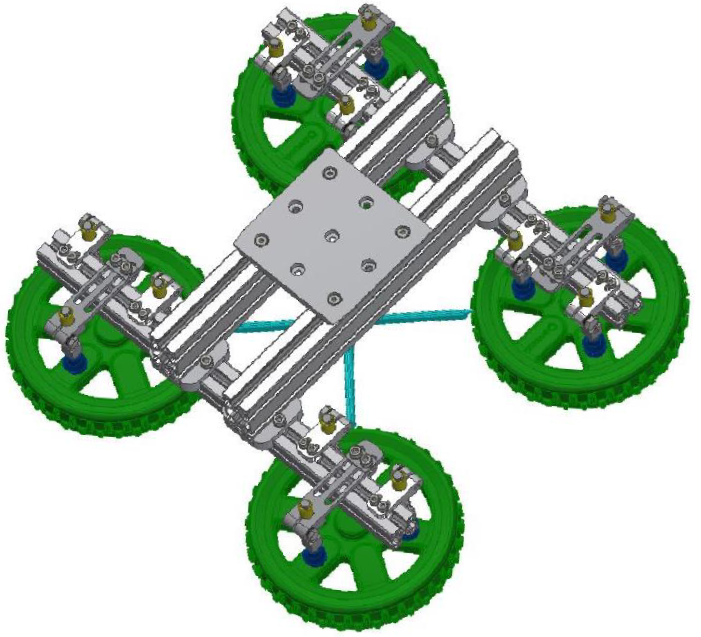

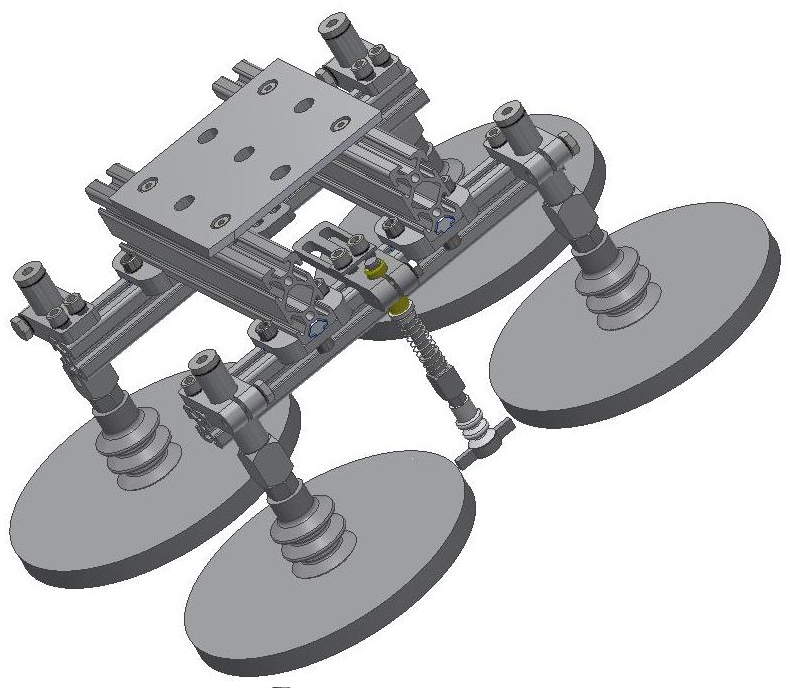

Complete gripper for removal of four Rims, wheels, wings ( from the tool The parts are removed with three low pressure suction cups per product in connection with spring loaded suction fingers

Button

Bildtitel

The products are removed with four low pressure suction cups per product in conjunction with spring loaded suction fingers the use of FDA compliant suction cups is possible here

Button

Bildtitel

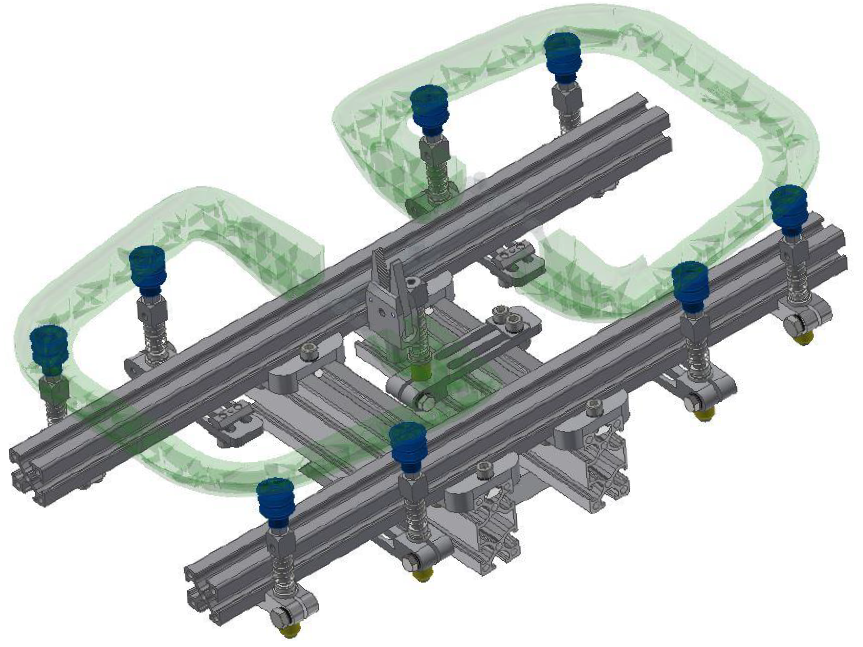

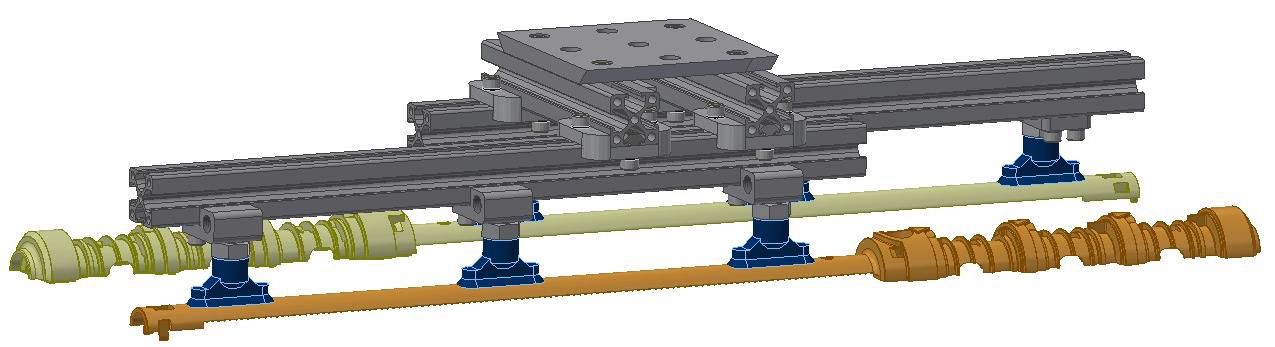

Removal of four parts with a total of twelve low pressure suction

cups per production cycle in conjunction with spring loaded suction fingers

Button

Bildtitel

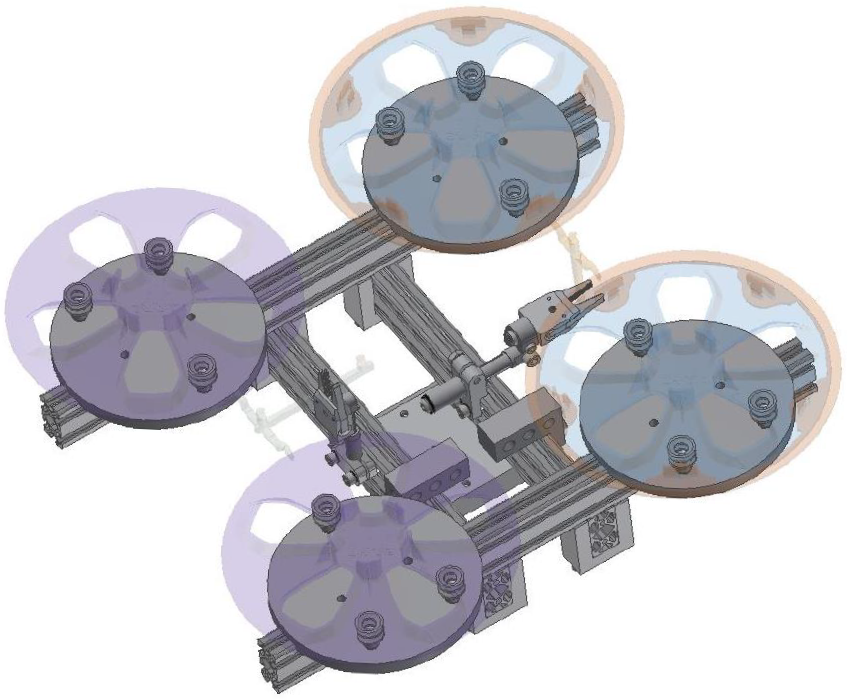

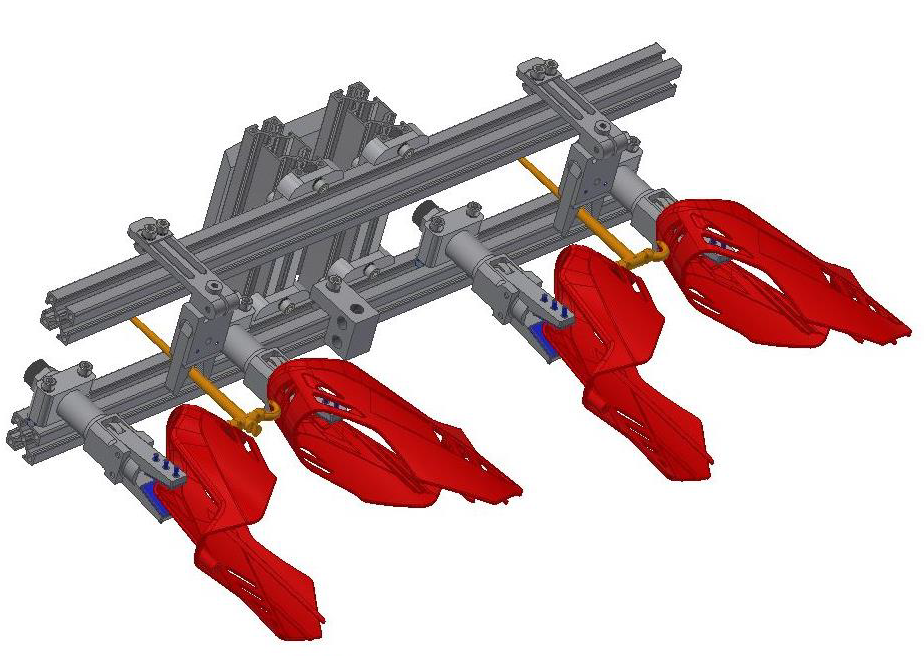

Removal of four parts is carried out with a total of four low pressure bellows suction cups per removal in conjunction with spring loaded suction fingers

(safe gripping of uneven surfaces is possible)

Button

Bildtitel

Complete gripper for removal or

pick'n place of half round, round articles (e.g., pipes) from a 2 cavity mold.

Button

Bildtitel

The parts are removed by means of grippers with coated jaw supports for low mark removal

Button

Bildtitel

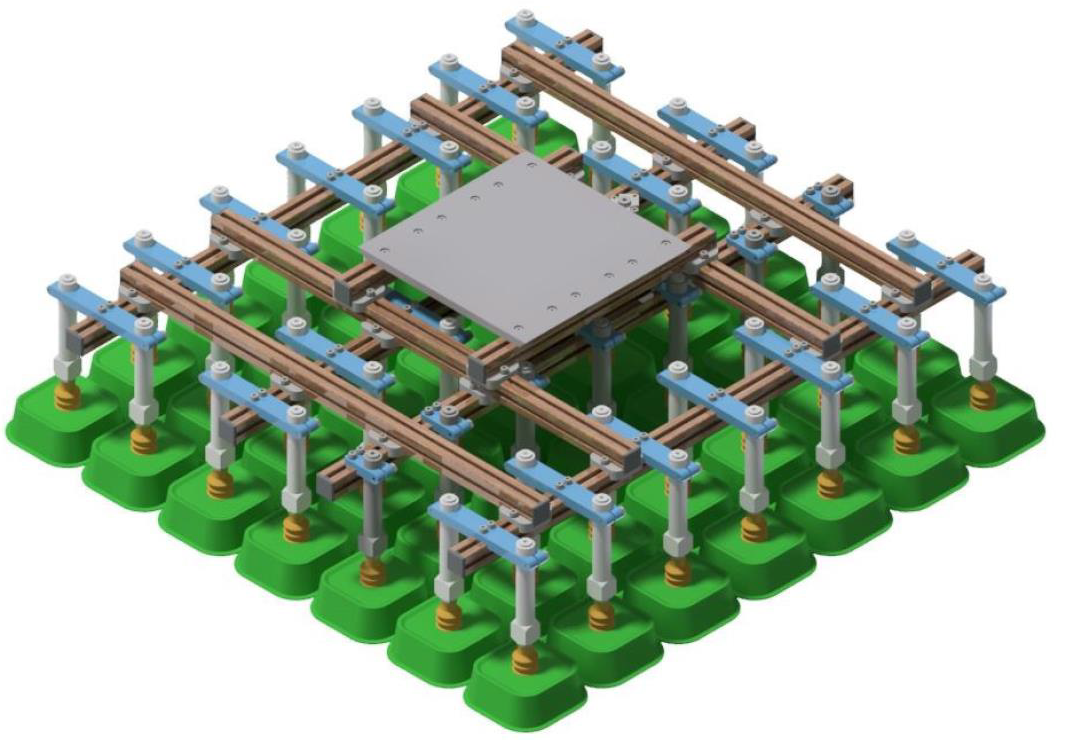

Complete gripper 49 fold for pick'n place of 49 assiettes,

cans, cups from the mold Parts

are removed by means of bellows suction cups made of low pressure, heat resistant or FDA conform material. Connecting

elements are acid resistant and rustproof

Button